It seems that the technology buzz du jour is blockchain. If you believe the hype, then blockchain will literally solve every problem under the sun and even technology problems that haven’t been discovered yet. While blockchain does have a significant revolutionary impact in some areas, namely financial transactions, unfortunately it isn’t the answer for every problem. Case in point is supply chain optimization.

Smart Manufacturing And Industry 4.0

Imagine that you had a collaborative Smart Manufacturing platform that gave you full visibility into not only what you have but the full history of how it was made such as where materials came from, how it was process and the quality at every step along the process. This is also the basis of Industry 4.0.

According to Wikipedia there are 4 components to the Industry 4.0 initiative include:

- Interconnection — the ability of machines, devices, sensors, and people to connect and communicate with each other via the Internet of things, or the internet of people (IoP)

- Information transparency — the transparency afforded by Industry 4.0 technology provides operators with comprehensive information to make decisions. Inter-connectivity allows operators to collect immense amounts of data and information from all points in the manufacturing process, identify key areas that can benefit from improvement to increase functionality

- Technical assistance — the technological facility of systems to assist humans in decision-making and problem-solving, and the ability to help humans with difficult or unsafe tasks

- Decentralized decisions — the ability of cyber physical systems to make decisions on their own and to perform their tasks as autonomously as possible. Only in the case of exceptions, interference, or conflicting goals, are tasks delegated to a higher level

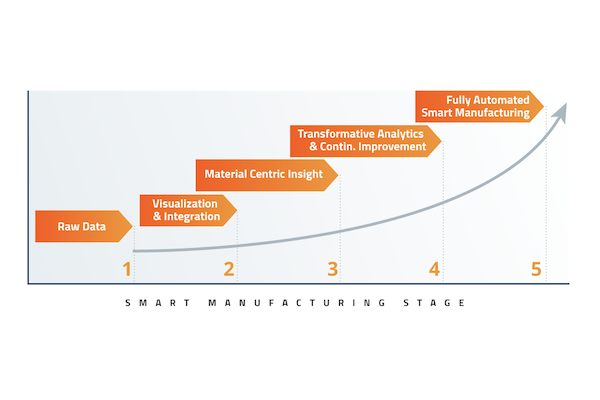

In order to achieve Industry 4.0 status, you will need to go through 5 levels of Smart Manufacturing:

- Data Capture

- Visualization & Integration

- Material-Centric Insight

- Transformational Intelligence

- Industry 4.0 Smart Manufacturing

So, this begs the question of what is the best approach to achieve Smart Manufacturing and Industry 4.0 status?

Blockchain Versus Material Ledger

Most everyone has heard the term blockchain, especially in relation to bitcoin. If you are not familiar with the concept, according to Wikipedia a blockchain is:

“…is a distributed database that maintains a continuously growing list of ordered records called blocks. Each block contains a timestamp and a link to a previous block. By design, blockchains are inherently resistant to modification of the data — once recorded, the data in a block cannot be altered retroactively. Through the use of a peer-to-peer network and a distributed timestamping server, a blockchain database is managed autonomously. Blockchains are "an open, distributed ledger that can record transactions between two parties efficiently and in a verifiable and permanent way. The ledger itself can also be programmed to trigger transactions automatically."

Unfortunately, blockchains also have a few known limitations as exposed by a ZDnet article titled “Don't believe the blockchain hype: Examining the weaknesses and risks” reported that:

“Blockchain, the platform underlying Bitcoin, is often described as 'inherently secure'. A new report reveals that it's far from ironclad.”

And 101Blockchains offers 12 points to be wary of in an article titled “Top Disadvantages of Blockchain Technology”

On the other hand, a Material Ledger is a novel approach to intelligently tracking material and energy movements and transformations, their associated monetary value, process data and quality data. An effective Material Ledger will have the following characteristics:

- Generic and industry neutral: While most MES systems are designed to track materials for a specific type of industry (typically discrete manufacturing) the material ledger is equally suited for discrete, batch, process and hybrid industries.

- Enables tracking of material/energy movements and transformations that happen over time: Traditional ledgers deal with transactions as something that happens at a point in time. In manufacturing this is not realistic as processes and material/energy movements happens over periods of time, typically as flows or processes that take time.

- Brings solid accounting principles to the plant floor and the supply chain: Built on the basics of double entry accounting, with manufacturing extensions. The association with core accounting principles makes it easy to understand, unlike other approaches such as ISA 95.

- Provides the core system for understanding manufacturing financials: Can track both amounts and balances for material/energy quantities and the associated monetary value. Enables the identification of accurate costing and value creation, can be used to calculate Return-On-Manufacturing-Assets (ROMA).

- Built in material balance verification: Every material transfer (send or receive) is related to an activity (material movement or material transformation) that ensures that inflows are balanced with outflows, providing material balance as a root feature. This makes it easy to find incorrectly entered information as well as identify material losses.

- Puts manufacturing process data and product quality data in context of material/energy movements, equipment model and time: Provides a unified way to correlate all manufacturing information independent of industry.

- Understands the concepts of first-in-first-out (FIFO), last-in-first-out (LIFO) and blended lots: Can be extended to support custom algorithms for partial blending.

- Root cause analysis: Makes it possible to identify correlation between incoming materials, performed process steps, and environmental conditions and the resulting quality of products produced.

- Product recalls: Identifies possible sources of contamination and a clear indication of which how big a recall should be.

- Reduces COGS through reduction of waste: Manufacturers with access to the information provided in the Material Ledger will be able to manage their supply chain better, identify issues and take corrective actions.

- Reduces Inventory requirements through reduction of variance and increased confidence in supply chain: By knowing what inventory is at hand, the status of the inventory and the usability of inventory for forecasted production, the inventory levels can be reduced and cash flow from operations can be increased.

So, understanding where blockchain versus a material ledger will have better impact for your organization, you should evaluate the core requirements as well as potential vendors that deliver on the promise.

Anonymous Financial Transactions Or Material Traceability

Ultimately, Blockchains and Material Ledgers are designed to solve two completely different problems. One is designed to ensure that electronic money can only be spent once, the other to keep track of material movements and provide context to process and quality data. The bottom line is that Blockchain is designed for tracking anonymous money and the heart of the ThinkIQ solution, our Material Ledger, is designed for tracking physical materials, energy and associated information.

ThinkIQ delivers unprecedented material traceability and insight into ways to improve yield, quality, safety, compliance and brand confidence. Our fact-based granular and data-centric contextualized view of material flows tracked in our material ledger, and related provenance attribute data, integrates into existing IoT infrastructures and crosses supply chains to manufacturing processes and beyond. Our customers have saved $10’s of millions by identifying waste and underperforming assets, as well as reducing warranty reserves for quality and safety issues.

With ThinkIQ, you can do a coloration between what you buy with what you make (Raw materials and what you do with them) and that just the beginning, both up and down your supply chain. ThinkIQ will provides all that process and transactional data and gives it meaning and puts it into context….for example take General Mills- when they buy grain, it has a certain quality and then you move it through the process (quality deteriorates)…handling grain poorly. You buy the right quality raw material and NOW you want to make sure that every step of the manufacturing process is adding more value than the cost associated with doing the process.

ThinkIQ technologies are designed and optimized to uncover information relevant to material movement and genealogy within time series data- This is true Plant and Performance Optimization:

- Adaptive semantic models that drive context discovery and management – ThinkIQ uncovers patterns in time series data by contextualizing data under various asset, structural and process models. The semantic graph technologies that underlie these models, drive accurate recognition and classification of events that occur at various points in time. The events recognized in turn decorate and augment the same models used to recognize patterns.

- Pattern recognition query engine optimized for time series data – ThinkIQ’s pattern recognition engine is optimized to uncover patterns in time series data, effectively fence posting events into specific time intervals under which they occur as defined by ThinkIQ event models. The engine combines these results to enable the discovery of important correlations in different time series data. This engine is intelligently guided by the semantic graph technology, allowing it to adapt to multiple conditions under which it needs to operate.

- Our technologies can contextualize multiple time series data sources along with traditional information sources, i.e. relational databases that power existing business systems. By combining operational data with transactional data, ThinkIQ can uncover unique insights into operational data that’s relevant for different business systems.

Now is the time to start your drive towards achieving Industry 4.0 or Smart Manufacturing status. Providing material traceability and analytics at all levels of the supply chain is at the start of this journey so you can lean more by downloading or eBook titled “Revolutionizing Digital Transformation in Manufacturing through Advanced Materials Traceability”, or better yet, request a demo today.