Machine Learning trained to watch for anomalies as part of a Safety Management System

When I started working summer jobs in construction and later worked as a materials/supply chain manager in back in the 1970’s, workplace safety was often an afterthought. I recall several near misses that occurred, especially the heavy equipment operator clipping overhead electrical wires while day dreaming, when I was clearing the field in front of him. Luckily, I stepped back when the live wires feel a few inches in front of my face. Many people were not as lucky as I was, and thank heavens, safety controls are much better today.

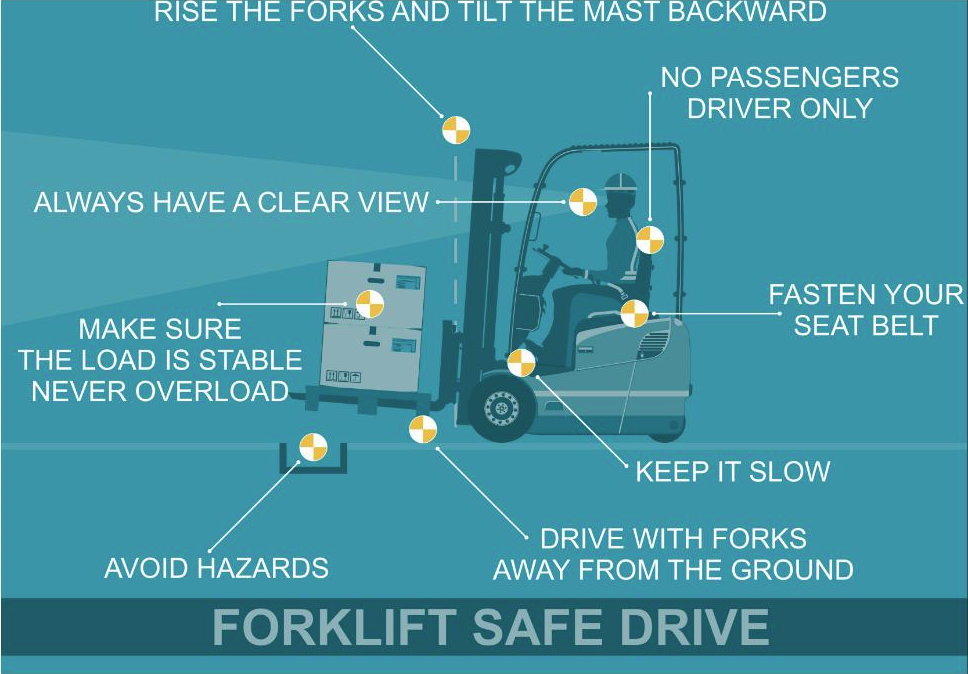

Unfortunately, some work environments will always present safety and compliance challenges. It is inevitable whenever people are interacting with a wide variety of vehicles, equipment and materials. These issues are compounded in areas with high labor turnover, language issues, and constant pressures to increase productivity.

As we have mentioned in earlier blogs, Computer vision provides an automated means to watch by wandering around. Unlike a manual supervisor, computer vision is 24x7, not in just one spot at a time, but in all critical areas of interest.

A primary focus of our first dozen customers in year one of operations has been to increase throughput, eliminate bottlenecks, and improve customer service. Now many of our newer customers and some of our existing customers are asking ThinkIQ to watch for a wide variety of compliance and safety issues. Their requirements are quite diverse, ranging from simple vehicle speeding violations to operators not wearing the proper safety equipment.

Computer vision has the unique ability to watch how people interact with the equipment they are operating, and materials or products they are working on. There are dozens of solutions that read machine and vehicle data, but only with computer vision can you be assured safety regulations are being followed. Only with computer vision it is possible to send auditable and/or visual alarms when:

- A person steps in an area that is deemed not safe.

- A person is standing behind a vehicle that is moving

- A driver makes an illegal U-turn or is going the wrong way

- An aircraft’s wheel chocks are not in place at the gate

- A vehicle is parked outside of designated areas

- A machine is operating with the safety door open

- A person is not wearing safety equipment – hardhat, safety glasses, etc.

Luckily, ThinkIQ’s solution uses off-the-shelf camera and computer hardware that operate wirelessly – so the installation process is easy, and the costs are low. The same cameras that watch for operational issues can multitask and send alerts when safety rules are violated.

No technology is fool proof, and to be effective the alerts will have to occur in near real time – within a second or two. But given what is a stake, computer vision can be an additive and cost-effective tool to improve overall any safety management system.