How do we actually use massive amounts of raw data?

Data - it’s everywhere. More than ever. The problem with this ever-expanding array of data is that it’s becoming increasingly overwhelming and difficult for organizations to manage, understand and effectively apply raw data using certain current technologies.

It doesn’t have to be this way.

Increasingly, manufacturing companies are embracing a digital transformation, understanding that raw data on its own is not enough - when it comes to turning raw data into raw power, the game changer lies in a shift towards advanced data analytics and continuous intelligence.

Harnessing Raw Data For Actionable Insights

In order for businesses to drive growth, it stands to reason that it’s the actionable insights generated from raw data that matter much more than the mere collection of the data itself.

What hinders manufacturing companies in successfully harnessing the true value of the copious amounts of raw data available can be attributed to a variety of factors:

- Manual collection dependent on the operators, as well as limitations in governance and processing procedures, can result in a lack in data quality and consistency.

- Data is often subject to improper or limited analysis, with a lack of context that enables discrepancies, waste, and inefficiencies in a manufacturing process.

- Data may not be displayed in a manner which allows its use to identify and resolve such problems,

- And frequently, data may not be available in a usable format until it’s too late to take crucial action.

Whether in the Mining Industry, the Chemical Industry, the Food & Beverage Industry or in Pharmaceutical Manufacturing, more and more manufacturing companies are overcoming these challenges by making the digital shift for exponentially improved analysis and contextualizing of the mountains of data at their disposal.

A digital transformation involves the implementation of continuous intelligence and the technologies of Industry 4.0 and Smart Manufacturing, making the most of raw data for a myriad of benefits:

- The collection of consistent, high quality data through devices such as Industrial Internet of Things (IIoT) sensors.

- The centralization of data onto one screen, one single source of truth.

- The contextualization of data, with early warning alerts that point to problems, mitigating risk, preventing recalls, and improving yield.

- The correlation of data using advanced Artificial Intelligence (AI) and Machine Learning (ML), providing greater supply chain visibility, cause and effect identification, and cross-plant KPIs, and identifying previously unseen root issues.

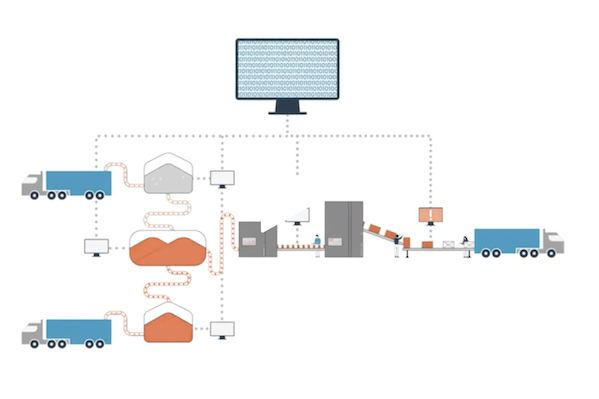

- The maximization of the full value of raw data through continuous intelligence that allows for fully autonomous Smart Manufacturing — traceability from raw materials to end product, predictive and prescriptive analytics to facilitate decisive action and prevent issues before they occur, and realtime, contextualized data across the entire manufacturing process.

The data explosion we are experiencing need not pose a threat to an organization’s survival; rather, companies now have access to a world of opportunity through digital transformation, and recognizing the true value the advanced data analytics of Smart Manufacturing provides to the growth and success of businesses today.

It's Time To Transform Your Raw Data

A transformation from raw data to raw power requires a capable guide and partner.

ThinkIQ is the leader in Transformational Intelligence for Manufacturers, transforming companies from using raw data to achieving complete Industry 4.0 Smart Manufacturing status. Such a revolutionary shift may seem daunting, but ThinkIQ ensures the transformation is implemented in manageable increments, offering significant benefits at each step.

Using a fact-based granular, data-centric contextualized view of material flows and related providence attribute data, ThinkIQ’s Transformational Intelligence platform allows companies to gain access to unprecedented material traceability and insight into ways to improve yield, quality, safety, compliance, and brand confidence while reducing waste and environmental impact — all made possible by collecting raw data across the value chain from existing IIoT sensors and business systems, and contextualizing it in realtime through continuous intelligence.

Simply put, actionable end-to-end data insights lead to safer products and improved key metrics.

In order to stay relevant in today’s digital age, it has become critical for manufacturing organizations to take seriously an investment in advanced data analytics and continuous intelligence. At ThinkIQ, we don’t just gather data. We don’t just analyze data. We make sense of the data, and suggest actions that enhance safety, reliability, and efficiency — resulting in the kind of raw power that revolutionizes companies for unprecedented growth and profitability.

From raw data to raw power — let’s get you started on the journey to digital transformation. Talk to a ThinkIQ expert today to learn more about achieving a vital competitive advantage through Industry 4.0 Smart Manufacturing. We also have a guide eBook to help you better understand the questions you should be asking. Download your copy today.