Big data is revolutionizing industries from healthcare to finance, and food manufacturing is no exception. In fact, the food and beverage industry might be one to gain the most, thanks to the arrival of material flow analytics, an advancement that creates a new level of supply chain visibility. A recent survey found that 82% of manufacturers currently experience low to moderate supply chain visibility, so it’s only logical that we can expect significant technology improvements in the coming years

While the use of material flow analytics is accelerating for world-renowned brands, its’ journey is just beginning for many food manufacturers. Read on to learn about Material Flow Analytics—and how it can impact the food and beverage manufacturing industry.

What Is Material Flow?

Material flow refers to the journey that raw materials take to reach their final status as a consumer product. In the case of the food manufacturing industry, material flow refers to the journey that raw foods, like potatoes, take to reach their final status as packaged foods. For example, the process of a potato being made into a French fry would look something like this:

- How, when and the types of potatoes that are harvested

- How potatoes travel to storage

- The conditions in which potatoes are stored

- How quickly potatoes deteriorate in storage

- How potatoes are transported from storage to production, including the length of storage time, cleaning and sorting processes

- How potatoes are prepared, including steaming, peeling, blanching, frying, freezing, and packaging

- How end-product of packaged French fry potatoes are transported to stores

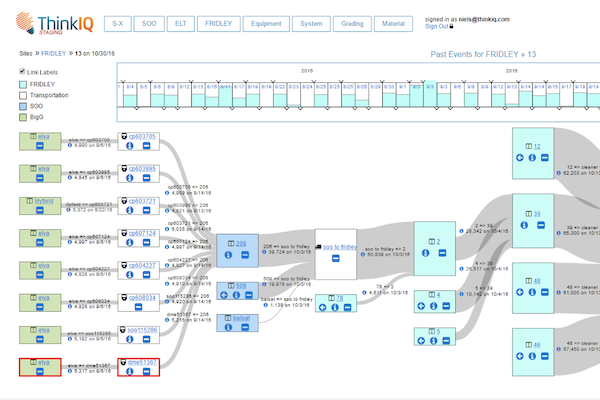

To simplify it, Material Flow Analytics refers to the review and analysis of the data collected during each process of the potato manufacturing lifecycle. The above image is a visual example of this process in action.

Why Are Material Flow Analytics Important?

For food manufacturers, there are two main reasons why material flow analytics are important:Actionable Insights

Typically, maximizing yield of your raw materials is a key objective for lowering and controlling costs. Most food manufacturers today analyze many parts of their processes to identify inefficiencies, but typically those efforts are focused on OEE (machine efficiency) and are limited to inside the four walls of the manufacturing environment. With material flow analytics, you can gather information about the raw materials, quality attributes, movement, and equipment involved in the process of creating your final food product. Then, you can correlate that information to the quality and yield of the process. For example, analytics affords you the opportunity to correlate a certain method of potato storage with the quality of the French fry. You might identify storage unit CO2 levels are impacting your end product, with the fries being crispier for example. These correlations can help to also identify areas of machine inefficiency, production, and energy waste. This information can be significantly impactful (upwards of 50% waste reduction) on the financial health and profitability of a company or product line. These insights are not just interesting, they are actionable! When you have the ability to identify factors that impact yield, waste and other manufacturing attributes, you can make business choices that allow you to optimize resources and economic output.

Provenance

[Provenance; (from the French provenir, ‘to come from/forth’) is the chronology of the ownership, custody or location of a historical object.] In some cases, material flow is important because consumers—and investors—need to know the provenance of your products. For example, investors might want to ensure that your brand uses the highest quality of raw material available, with minimal waste. Material flow analytics can easily prove the provenance of your foods, and the amount of waste. There are some cases in which the provenance of food is critical for other reasons. For example, the origin of the product might be relevant if there is an outbreak of foodborne illnesses, or if the product is originating from a country that is known to inflict human rights abuses, on-field workers. Your business stakeholders need to be confident that can validate product history.

How Does a Manufacturer Track Material Flow?

With today’s Internet of Things (IoT) and big data technology, tracking material flow is now a realistic possibility. With ThinkIQ, manufacturers can leverage their existing assets so there is no need to make expensive upgrades to hardware or software. Similarly, there is no need to “rip and replace” other components of the manufacturing process. ThinkIQ uses current investments in hardware and software, so manufacturers can just install physical sensors (if needed) to automate manual processes throughout their factories and locations. These sensors do not affect the flow of product, they collect data that defines material movements, quality attributes, material locations, and other critical information. With these data points, the material flow analytics platform will identify granular correlations, letting your business know where it helps solve key opportunities like over/under consumption, food safety events, reduction of waste, production within client specifications and yield improvement.

The Difference Between Material Flow Analytics And Traceability

Material flow and traceability are similar but vastly different? Traceability refers to the smart tracking of items that have a unique identifier (i.e. serialized parts, RFID tags, barcodes) Computers, for example, often have distinctly marked central processing units (CPUs). They can be tracked easily, no matter whether they’re in the manufacturing plant or on their way to a repair shop. Material flow deals with products that are not traceable easily traceable—like raw food items. For example, you can’t attach an RFID tag to a potato; it would be an unpleasant, crunchy surprise for consumers. Instead, food manufacturers can use existing sensors to track their food products throughout production

Overview

For food manufacturers, maximizing yield is the best way to increase profits. Historically, food manufacturers have focused on analyzing equipment efficiency, today they can use advanced material flow analytics to track and improve the journey of their raw materials.